High-Performance Linear Actuators for Additive Manufacturing

For 3D printing machines which utilize advanced additive manufacturing techniques such as Selective Laser Sintering (SLS) and Selective Laser Melting (SLM), a precise linear positioning system is required to produce accurate 3D printed parts.

ATLANTA has developed a range of High Performance Linear Actuators to solve the demands of these types of applications.

Selective Laser Sintering (SLS) is an additive manufacturing technique that uses a high power laser to sinter (or fuse) small particles of plastic, metal, ceramic or glass powders into a solid structure. The laser selectively fuses the powdered material by scanning cross-sections generated from a 3D model on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top and the process is repeated until the part is completed.

Selective Laser Melting (SLM) is similar to selective laser sintering (SLS), but can be used to fully melt the powder, rather than heating it up to the point where the powder grains fuse together. This allows the powder to liquefy long enough to melt the powder grains into a homogeneous part. SLM can produce stronger parts because of reduced porosity and better control over the crystal structure.

Precise Positioning of the Powder Bed

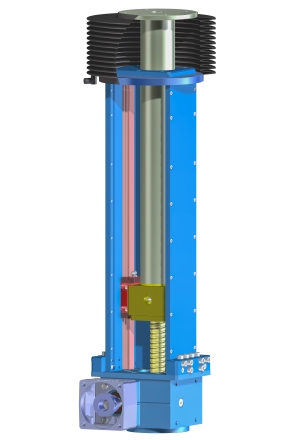

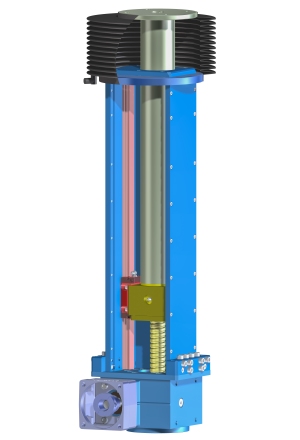

ATLANTA High-Performance Linear Actuators can be used to precisely control the position of the powder bed, lowering it by one layer thickness, which is typically 20 to 100 micrometers (0.0008” to 0.0040”) thick. The actuator also supports the weight of the powder bed and once the part is complete, can return the bed to the home position to start another part.

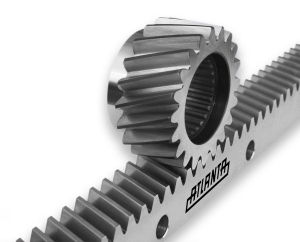

The ATLANTA linear actuators utilize precision ballscrew spindles and zero-backlash nuts enclosed in protective housings, driven directly by high-precision servo-worm reducers. The moving spindle extension is protected with a bellows to prevent powder intrusion.

For a 350 mm stroke length, the following positioning accuracies could be achieved:

• Diagonal movement: 0.20 mm (0.008”)

• Turning movement: 0.20 mm (0.008”)

• Maximum concentricity: 0.50 mm (0.020”)

Linear Guide Protection

Linear guides are typically required to guide the powder bed in a controlled manner, but if they are not adequately protected, the powder can contaminate the rails and carriages and lead to premature failures.

To solve this problem, ATLANTA has also developed special linear actuators with an integrated linear rail and carriage that is fully enclosed in the actuator. This eliminates any contamination concerns and allows the actuator to guide the powder bed more precisely.

By integrating the linear guide into the linear actuator, the positioning accuracy is improved further:

• Diagonal movement: 0.04 mm (0.0015”)

• Turning movement: 0.01 mm (0.0004”)

• Maximum concentricity: 0.08 mm (0.0031”)

Vacuum Environment Applications

For some 3D printing applications, the powder bed is required to operate within a vacuum, due to the processes being performed. To solve this problem, ATLANTA linear actuators can also be provided with seal surface on the ballscrew to allow for vacuum operation while having the servo-worm reducer drive from outside the vacuum environment.

Summary

3D printing machines which utilize advanced additive manufacturing techniques require advanced linear drive systems to allow them to produce accurate parts.

ATLANTA’s linear actuators for additive manufacturing solve these requirements, including precise positioning, linear guide protection and vacuum operation. Other benefits offered include:

• Bellows protection for preventing powder intrusion

• Zero-backlash ballscrew spindle and nut

• Protective housing for internal components

• Precision servo-worm reducer drive