Precision Planetary Reducers

Reducers with Output Shaft

Reducers with Output Flange

This standard range of Precision Planetary Reducers are perfect for use in applications that demand high performance, precise positioning and repeatability. They were specifically developed for use with state-of-the-art servo motor technology, providing tight integration of the motor to the unit. Design features include mounting any servo motors (IEC, NEMA, or customized motors), standard low backlash, high torsional stiffness, 95 to 97% efficiency and quiet running.

They are available in nine sizes with reduction ratios from 3:1 to 600:1 and output torque capacities up to 16,227 lb.ft. The output can be provided with a solid shaft or ISO 9409-1 flange, for mounting to rotary or indexing tables, pinion gears, pulleys or other drive elements without the need for a coupling. For high precision applications, backlash levels down to 1 arc-minute are available. Right-angle and input shaft versions of these reducers are also available.

Typical applications for these reducers include precision rotary axis drives, traveling gantries & columns, material handling axis drives and electronic line shafting. Industries served include Material Handling, Automation, Aerospace, Machine Tool and Robotics.

- Unit Design &

Construction - Unit Selection

- Unit Ratings for

Output Shaft - Unit Ratings for

Output Flange

Gearing: Featuring HeliCamber® case-hardened & ground gearing with minimal wear, low backlash and low noise, making them the most accurate and efficient planetaries available. Standard planetary design has three planet gears, with a higher torque version using four planets also available, please see the Reducers with Output Flange chart on the Unit Ratings tab under the "+" unit sizes.

Bearings: Optional output bearing configurations for application specific radial load, axial load and tilting moment reinforcement. Oversized tapered roller bearings are standard for the ISO Flanged Reducers.

Housing: Single piece steel housing with integral ring gear provides greater concentricity and eliminate speed fluctuations. The housing can be fitted with a ventilation module to increase input speeds and lower operational temperatures.

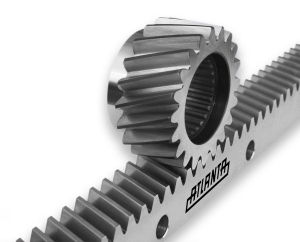

Output: Available in a solid shaft with optional keyway or an ISO 9409-1 flanged interface. We offer a wide range of standard pinions to mount directly to the output style of your choice.

These reducers are typically selected based on the peak cycle forces, which usually happen during accelerations and decelerations. These cycle forces depend on the driven load, the speed vs. time profile for the cycle, and any other external forces acting on the axis.

For application & selection assistance, please call, fax or email us. Your application information will be reviewed by our engineers, who will recommend the best solution for your application.

The following table gives the technical specifications for the Precision Planetary Reducers with solid output shafts.

Service factors need to be applied to these ratings to make a proper selection.

To see the unit dimensions of each size, click the "Unit Size" in the left column.

| Unit Size |

Stages | Available Ratios | Accel. Torque (lb.ft.) | Max. Input Speed* | Torsional Backlash** (arc-minutes) |

Torsional Stiffness (in.lb/arcmin) |

Efficiency (η) |

|---|---|---|---|---|---|---|---|

| 2 | 1 | 4, 5, 7, 8, 10 | 16.3 | 8,000 | 6 | 16.8 | 97% |

| 2 | 16, 20, 25, 28, 32, 35, 40, 50, 70, 100 | 8,000 | ≤ 8 | 95% | |||

| 3 | 1 | 3, 4, 5, 7, 8, 10 | 47.9 | 8,000 | ≤ 4 (≤ 2) | 50.5 | 97% |

| 2 | 15, 16, 20, 25, 28, 32, 35, 40, 50, 70, 100 | 8,000 | ≤ 5 (≤ 3) | 95% | |||

| 4 | 1 | 3, 4, 5, 7, 8, 10 | 87.7 | 7,000 | ≤ 4 (≤ 2) | 110 | 97% |

| 2 | 15, 16, 20, 25, 28, 32, 35, 40, 50, 70, 100 | 8,000 | ≤ 5 (≤ 3) | 95% | |||

| 5 | 1 | 3, 4, 5, 7, 8, 10 | 221 | 6,500 | ≤ 3 (≤ 1) | 321 | 97% |

| 2 | 15, 16, 20, 25, 28, 32, 35, 40, 50, 70, 100 | 7,000 | 4 (≤ 2) | 95% | |||

| 7 | 1 | 3, 4, 5, 7, 8, 10 | 516 | 6,000 | ≤ 3 (≤ 1) | 571 | 97% |

| 2 | 15, 16, 20, 25, 28, 32, 35, 40, 50, 70, 100 | 6,500 | 4 (≤ 2) | 95% | |||

| 8 | 1 | 3, 4, 5, 7, 8, 10 | 1,180 | 4,500 | ≤ 3 (≤ 1) | 1948 | 97% |

| 2 | 15, 16, 20, 25, 28, 32, 35, 40, 50, 70, 100 | 6,000 | 4 (≤ 2) | 95% | |||

| 9 | 1 | 4, 8, 7, 10 | 2,214 | 4,000 | ≤ 3 (≤ 1) | 3093 | 97% |

| 2 | 16, 20, 25, 28, 35, 40, 50, 70, 100 | 4,500 | 4 (≤ 2) | 95% |

*Values for cyclic duty; Higher input speeds can be achieved using a ventilation module.

**Reduced backlash units available.

The following table gives the technical specifications for the Precision Planetary Reducers with ISO 9409-1 flanged outputs.

Service factors need to be applied to these ratings to make a proper selection.

To see the unit dimensions of each size, click the "Unit Size" in the left column.

| Unit Size |

Stages | Available Ratios | Accel. Torque (lb.ft.) | Max. Input Speed* | Torsional Backlash** (arc-minutes) |

Torsional Stiffness (in.lb/arcmin) |

Efficiency (η) |

|---|---|---|---|---|---|---|---|

| 3 | 1 | 5, 7, 10 | 47.9 | 6,000 | ≤ 3 (≤ 1) | 115 | 96% |

| 2 | 20, 25, 28, 35, 40, 50, 70, 100 | 8,000 | 94% | ||||

| 4 | 1 | 4, 5, 7, 10 | 95.8 | 6,000 | ≤ 3 (≤ 1) | 346 | 96% |

| 2 | 16, 20, 25, 28, 35, 40, 50, 70, 100 | 8,000 | 94% | ||||

| 5 | 1 | 4, 5, 7, 10 | 236 | 6,000 | ≤ 3 (≤ 1) | 868 | 96% |

| 2 | 16, 20, 25, 28, 35, 40, 50, 70, 100 | 7,000 | 94% | ||||

| 7 | 1 | 4, 5, 7, 10 | 516 | 5,000 | ≤ 3 (≤ 1) | 1,639 | 96% |

| 2 | 16, 20, 25, 28, 35, 40, 50, 70, 100 | 6,500 | 94% | ||||

| 7+ | 2 | 22, 27.5, 38.5, 55 | 700 | 6,500 | ≤ 3 (≤ 1) | 1,837 | 90 - 93% |

| 3 | 88, 110, 137.5, 154, 192.5, 220, 275, 385, 550 | 7,000 | |||||

| 8 | 1 | 4, 5, 7, 10 | 1,475 | 4,000 | ≤ 3 (≤ 1) | 5,315 | 96% |

| 2 | 16, 20, 25, 28, 35, 40, 50, 70, 100 | 6,000 | 94% | ||||

| 8+ | 2 | 22, 27.5, 38.5, 55 | 1,917 | 6,000 | ≤ 3 (≤ 1) | 5,855 | 90 - 93% |

| 3 | 88, 110, 137.5, 154, 192.5, 220, 275, 385, 550 | 6,500 | |||||

| 9 | 2 | 12, 16, 18 ,20, 24 28, 30, 32, 40, 42, 48, 60 | 3,690 | 4,500 | ≤ 3 (≤ 1) | 10,980 | 96% |

| 3 | 61, 91, 121 | 4,500 | 94% | ||||

| 9+ | 2 | 18, 24, 30, 42, 60 | 4,425 | 4,500 | ≤ 3 (≤ 1) | 10,961 | 90 - 93% |

| 3 | 72, 96, 120, 150, 168, 210, 240, 300, 420, 600 | 6,000 | |||||

| 10 | 2 | 18, 24, 30, 42, 48, 60 | 5,531 | 4,500 | ≤ 3 (≤ 1) | 15,752 | 96% |

| 3 | 61, 91 | 4,500 | 94% | ||||

| 10+ | 2 | 24, 30, 42, 60 | 7,376 | 4,000 | ≤ 3 (≤ 1) | 18,320 | 90 - 93% |

| 3 | 96, 120, 150, 168, 210, 240, 300, 420, 600 | 4,500 | |||||

| 11+ | 2 | 24, 30, 42, 60 | 16,227 | 3,800 | ≤ 3 (≤ 1) | 31,225 | 90 - 93% |

| 3 | 96, 120, 150,

168, 210, 240, 300 |

4,500 |

*Values for cyclic duty; Higher input speeds can be achieved using a ventilation module.

**Reduced backlash to 1 arc-minute available.