ATLANTA Drive Systems Offers Automatic Lubrication Systems for Rack & Pinion Drives

With open gearing such as rack & pinions, lubrication is extremely critical. A thin film of grease should always be present on the contacting tooth flanks to ensure that there is no metal-to-metal contact, which can quickly damage the teeth. Manual lubrication (applied by hand) can be unreliable and inconsistent and reduce the lifetime of the gearing.

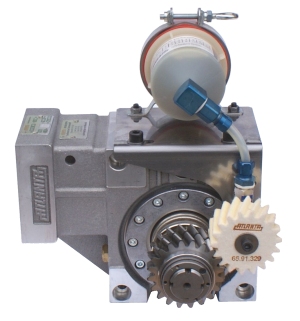

ATLANTA Drive Systems offers a complete range of Automatic Lubrication Systems, which precisely pump grease through a felt gear applicator directly to the rack and pinion teeth. This provides continuous lubrication to the tooth flanks, extending the lifetime and maintaining the quality of the gearing.

To pump the grease lubricant, lubricators are available in two sizes (125 cc and 475 cc) with options for battery operation or externally powered. The lubricator flow rate is controlled by a set of DIP switches, which can adjust the emptying time of the lubricator from one month to eighteen months. The amount of lubricant required per day depends on the size (module) and the linear operating speed of the rack & pinion drive.

The operation of the Automatic Lubrication Systems can be synchronized with the machine operation by use of a contact cable, so the grease only flows when needed. It is also possible to electronically detect when the lubricator is empty and needs to be refilled or replaced.

For more information, contact ATLANTA Drive Systems at: (800) 505-1715, or on the web at: www.atlantadrives.com.