Related Resources

Operating Manuals Automatic Lubrication Systems PDF Application Sheets Frequently Asked QuestionsOther Products Available

Automatic Lubrication Systems

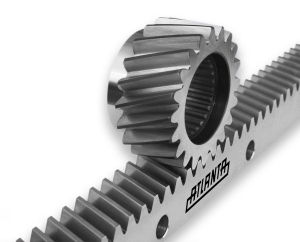

With open gearing such as rack & pinions, lubrication is extremely critical. A thin film of grease should always be present on the contacting tooth flanks to ensure that there is no metal-to-metal contact, which can quickly damage the teeth.

All of our rack & pinion load ratings are based on adequate grease lubrication. If adequate lubrication is not provided to the rack & pinion tooth flanks, their loading carrying capacity and lifetime will be reduced.

Manual lubrication (applied by hand) can be unreliable and inconsistent and reduce the lifetime of the gearing. It is highly recommended to use our Automatic Lubrication Systems, which precisely pump grease through an applicator directly to the rack and pinion tooth flanks. This provides continuous lubrication at the tooth flanks, extending the lifetime and maintaining the quality of the gearing.

Although it is not recommended, it is possible to run our Rack & Pinions without lubrication. To discuss the limitations and concerns of running dry, please consult the factory.

For more detailed information on our Automatic Lubrication Systems, please check out the PDF catalogs here:

- Complete Automatic Lubrication Systems - Type 125 & 475 Automatic Lubricators - Type M60, M150 & M250 Automatic Lubricators - Type MD125 Automatic Lubricators - Type MD400 Automatic Lubricators- Automatic

Lubricators - Lubricant

Applicators - Recommended

Lubricants

To supply the lubricant to the applicator, ATLANTA has a full line of Automatic Lubricators with capacities up to 475 cc and fully adjustable flow rates with emptying times up to thirty six months.

To supply the lubricant to the applicator, ATLANTA has a full line of Automatic Lubricators with capacities up to 475 cc and fully adjustable flow rates with emptying times up to thirty six months.

These lubricators can be operated with batteries or externally powered and can be synchronized with the machine operation so the grease only flows when needed. The smaller lubricators (125, 475, M60, M150 and M250) can generate up to 7.5 bar of internal pressure and are best suited for single-point lubrication; the larger lubricators (MD125 and MD400) can generature up to 70 bar of internal pressure and can hande multi-point lubrication.

It is also possible to electronically detect when the lubricator is empty and needs to be refilled or replaced.

| Lubricator Model | Sizes | Pump Type | Max. Pressure | Power | Control |

|---|---|---|---|---|---|

| 125 / 475 (Classic) | 125 & 475 cc | Chemical | 3 Bar | Batteries or 3V External |

Dip Switches & Contact Cable |

| M60 / M150 / M250 | 60, 150, 250 cc | Mechanical | 7.5 Bar | Batteries or 24V External |

Dip Switches |

| MD125 | 125 & 250 cc | Mechanical | Up to 50 Bar | Batteries or 24V External |

LED Display |

| MD400 | 250 & 400 cc | Mechanical | Up to 70 Bar | Batteries or 24V External |

LED Display or PLC |

When mounting the Automatic Lubricators, the lubricator should be located below the applicator discharge point, so the grease does not flow by gravity. Ideally, the lubricator should also be mounted sideways or upside down to prevent undesired flow. If this is not possible, then a non-return valve should be used before the applicator.

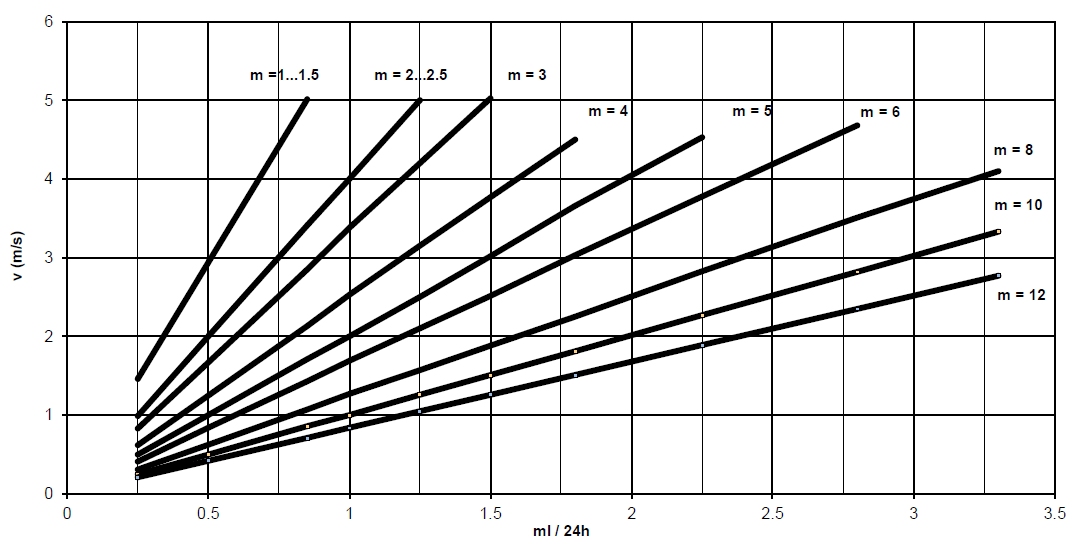

The amount of lubricant required per day depends on the gearing size (module) and the linear operating speed (v), please see graph below.

Example: For a module 3.0 rack and pinion running at 2.0 meters per second, the required lubricant flow rate per day would be ~0.63 cc. Using a 125 cc lubricator, the dip switch setting to achieve this flow rate would be #5 and #7 (switches #1 through #6 adjust the flow rate; #7 switch turns the lubricator on and makes light blink).

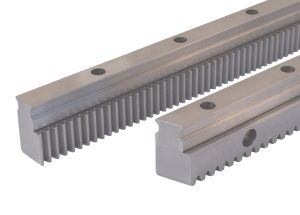

We have two different lubricant applicators available: a brush and felt gear. The brush can be located near the gear mesh and although it can provide continuous lubrication, it can not precisely place the lubricant at the gear mesh. This should only be used when the felt gear applicator is not practical.

To precisely place the lubricant at the gear mesh, a felt gear applicator should be used. The felt gear is actually a gear made out of felt that can mesh directly with the pinion or rack to supply the lubricant. The lubricant flows through a mounting shaft and directly in-between the teeth of the felt gear. Ideally, the felt gear should mesh with the pinion, since it sees the most cycles. By meshing directly with the pinion or rack, the felt gear can provide continuous lubrication to the tooth flanks before they are loaded.

The felt gear should be primed with lubricant before it is mounted into the machine.

We have the most experience with grease lubrication, which typically does not flow and stays where you apply it. When using our felt gear applicators, we recommend Kluber Structovis AHD grease. Kluber Microlube GB0 can also be used, but does not flow as well through the felt gear.

Other greases that have been tested with good results include: Oest Langezeitfett LT 200, BP Energrease LS EP 00, DEA Glissando 6833 EP00, Fuchs Lubritech Gearmaster ZSA and Molykote G-Rapid plus 3694.

We do not recommend oil lubrication because it will flow away from the tooth flanks.