Servo Reducers

ATLANTA Drive Systems, Inc. is pleased to announce the expansion of our range of Servo Reducers, now offering five levels of precision to meet any application requirements. The five levels of precision available allows a machine designer to select the required reducer precision to meet their needs and their budget. They are available in both in-line and right-angle versions, in torques up to 7,376 lb.ft. and ratios to 3,392:1.

Typical applications for these reducers include rotary & linear axis drives, and material handling axis drives. Industries served include Material Handling, Automation, Aerospace, Machine Tool and Robotics.

- Product Range

Available - Product Range

Overview - PDF Catalog Files

- Reducer Selection

High-Performance (HP) 58-Series

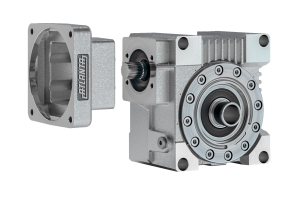

The High-Performance (HP) Series is the original Servo-Worm Reducer, available in five sizes (50 mm to 125 mm center distance) with a backlash level of less than two arc-minutes.

High-Torque (HT) 98-Series

The High-Torque (HT) Series offers 150% the torque capacity of the HP Series, while reducing the backlash level to less than one arc-minute. The output was also redesigned for increased bearing capacity and an option for ISO 9409-1 flanged connections.

Economy (E) 59-Series

The Economy (E) Series offers the same torque capacity as the HP Series, with a fixed backlash level of less than five arc-minutes. A simplified housing and assembly allows for significant price savings.

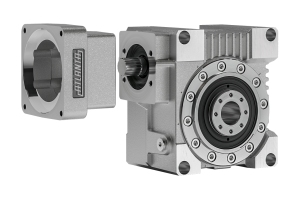

Precision Planetary Reducer Series

The Precision Planetary Reducer Series offers a wide range of sizes and output configurations, including solid shaft and ISO 9409-1 flange, with ratios from 3:1 to 600:1 and backlash levels down to less than one arc-minute.

Click on the "Version" name to view PDF file on specific unit; click on the "Torque Capacities" of unit to view full unit ratings.

| Version | High Torque HT |

High Performance HP |

Economy E |

Planetary |

|---|---|---|---|---|

| Center Distances |

50 to 100 mm |

50 to 125 mm |

32 to 100 mm |

--- |

| Backlash Level |

< 1 arc-min | < 2 arc-min | < 5 arc-min | < 1 arc-min |

| Output Styles |

Flanged & Compression |

Keyed & Compression |

Keyed & Compression |

Keyed & Flanged |

| Torque Capacities |

885 lb.ft. | 1,143 lb.ft. | 590 lb.ft. | 7,376 lb.ft. |

The mounting faces of the HT, HP and E versions are identical, making it possible to interchange a unit with a higher or lower accuracy unit if needed.

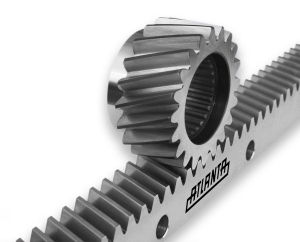

A wide range of motor couplings and mounting flanges are available for the complete reducer range to mount virtually any servo motor and the hollow bore output can be used to mount output shafts, pinion shafts, or other drive elements.

- Unit Selection

- Unit Specifications & Dimensions

- Motor Mounting Guide & List

These reducers are typically selected based on the peak cycle forces, which usually happen during accelerations and decelerations. These cycle forces depend on the driven load, the speed vs. time profile for the cycle, and any other external forces acting on the axis. For more selection information, please follow this PDF link.

For application & selection assistance, please call, fax or email us. Your application information will be reviewed by our engineers, who will recommend the best solution for your application.