Other Products Available

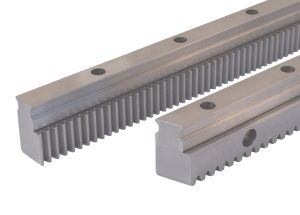

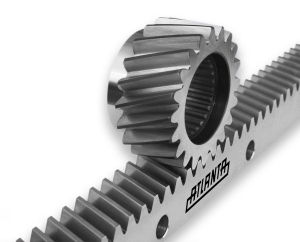

Gear Racks

Welcome to the widest range of standard racks & pinions in the World! Consisting of both helical & straight (spur) tooth versions, in an assortment of sizes, materials and quality levels, to meet almost any axis drive requirements.

These drives are perfect for a wide range of applications, including axis drives requiring precise positioning & repeatability, traveling gantries & columns, pick & place robots, CNC routers and material handling systems. Heavy load capacities and duty cycles can also be easily handled with these drives. Industries served include Material Handling, Automation, Automotive, Aerospace, Machine Tool and Robotics.

The rack product range consists of metric pitches from module 1.0 to 16.0, with linear force capacities of up to 92,000 lb. Rack styles include helical, straight (spur), integrated and round. Rack lengths up to 3.00 meters are available standard, with unlimited travels lengths possible by mounting segments end-to-end. Quality levels available include soft, induction-hardened, quenched & tempered and hardened & ground (up to AGMA 12+ and DIN 4).

Typical delivery time for these standard components is 2 to 3 weeks, which is ideal for OEM's requiring just-in-time delivery schedules. Special and/or modified components are always possible - please consult the factory. For harsh environments, stainless steel rack & pinions are available, as well as coatings such as black oxide and chromium (Armoloy ®).

Advantages of Using Long Racks: Through continuous improvements in production techniques, ATLANTA has been able to reduce the total pitch error for the 1,000 mm long hardened & ground racks, while achieving significant reductions of the total pitch error of 1,500 mm and 2,000 mm long hardened & ground racks.

Replacing Diametral Pitch Racks: For information on replacing Diametral Pitch (DP) rack & pinions, please follow this link.

BRS Integrated Racks: For information on the special Integrated Racks that ATLANTA previously supplied to Bosch Rexroth, please follow this link.

- Rack Styles

Available - Rack Quality

Levels Overview - Selecting Right

Rack & Pinion - Rack Range

Overview - Lubrication

Helical versus Straight: The helical style provides several key benefits over the straight style, including:

- They run quieter than the straight, especially at high speeds

- They have a higher contact ratio (the number of effective teeth engaged) than straight, which increases the load carrying capacity

- Their lengths are nice round numbers, e.g. 500.0 mm and 1,000.0 mm, for easy integration with machine bed lengths; Straight racks lengths are always a multiple of pi., e.g. 502.65 mm and 1005.31 mm.

- In most cases, they cost the same as the straight racks!

There are four classes of gear racks available and eight different quality levels, each of which is well suited for certain types of applications. Click on Series Numbers for PDF catalog pages.

| Rack Class: | Rack Type: | Tooth Quality: |

Pitch Accuracy: |

Typical Applications: |

Helical: |

Straight: |

|---|---|---|---|---|---|---|

| Basic (BR) |

Induction Hardened |

DIN 10 (~AGMA 8) |

< 0.200 mm per meter |

Heavy Loads Low Accuracy |

39-Series | 27-Series 34-Series |

| Soft | DIN 9 (~AGMA 9) |

< 0.150 mm per meter |

Light Loads Medium Accuracy |

47-Series | 25-Series 36-Series (Stainless) |

|

| Precision (PR) |

Quenched & Tempered |

DIN 8 (~AGMA 10) |

< 0.100 mm per meter |

Medium Loads Medium Accuracy |

38-Series | 33-Series |

|

Hardened & Ground |

DIN 8 (~AGMA 10) |

< 0.060 mm per meter |

Heavy Loads High Accuracy |

29-Series | 28-Series | |

| High Precision (HPR) |

Hardened

& Ground |

DIN 7 (~AGMA 11) |

< 0.052 mm per meter |

Heavy

Loads High Accuracy |

29-Series | 28-Series |

| DIN 6 (~AGMA 12) |

< 0.036 mm per meter |

29-Series | 28-Series | |||

| Ultra-High Precision (UHPR) |

Hardened & Ground |

DIN 5 | < 0.026 mm per meter |

Heavy

Loads Ultra-High Accuracy |

29-Series | 28-Series |

| DIN 3 | < 0.012 mm per meter |

48-Series | 46-Series |

The quality levels denote the accuracy of the teeth, which affects the positioning accuracy, backlash and noise level of the rack & pinion set. We always recommend a hardened & ground pinion regardless of the rack type used.

When talking about rack & pinion accuracy, it can be broken down into three components: Backlash, Pitch Deviation and Tooth Quality.

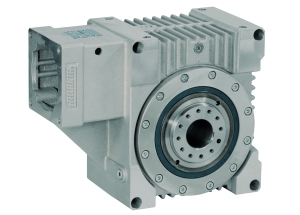

- Backlash is the amount of clearance between the rack & pinion tooth flanks, and will depend on the type of rack selected and alignment accuracy between the rack and pinion. The backlash can be eliminated completely by using a Preloaded Split-Pinion or Dual Pinion Drive System.

- Pitch Deviation is the difference between the theoretical rack length and its actual length. This varies depending on the rack quality selected and is shown in the catalog as GTf. Some servo systems can compensate for this error by using a laser interferometer to map out the errors. Zero cumulative pitch deviation for long travels is available - please consult the factory.

- Tooth Quality is the accuracy that the tooth flanks are manufactured to, which affects the running precision, smoothness, backlash and noise level of the axis drive. Soft racks have a quality level of ~AGMA 9 (DIN 9). Induction-hardened racks have a quality level of ~AGMA 8 (DIN 10), due to deformation from the heat treatment process. Quenched & Tempered racks have a quality level of ~AGMA 10 (DIN 8). Finally, Hardened & Ground racks have a quality level of ~AGMA 12 (DIN 6), since the teeth are precision ground. For high accuracy applications, a Precision Hardened & Ground Rack should be used.

*AGMA quality level numbers increase with higher precision; DIN quality level numbers decrease with higher precision.

Selecting the right gear rack and pinion depends on many things, including accuracy and load requirements, design constraints, and cost. Sometimes it is possible that two different racks would work for the same application, but each having it's own advantages and disadvantages.

Rack & pinions are typically selected based on the peak cycle forces, which usually happen during accelerations and decelerations. These cycle forces depend on the weight being moved, the speed vs. time profile for the cycle, the friction of the axis bearings, and any other external forces acting on the axis.

Tangential force ratings for the various racks can be seen in the following table:

| Rack & Pinion Size |

Tangential Force Ratings* | |||

|---|---|---|---|---|

| Hardened & Ground Rack |

Induction-Hardened Rack |

Quenched & Tempered Rack |

Soft Rack | |

| Module 1.5 | 1,600 lb. | 780 lb. | --- | 200 lb. |

| Module 2.0 | 4,100 lb. | 2,000 lb. | 1,100 lb. | 560 lb. |

| Module 3.0 | 6,700 lb. | 3,400 lb. | 1,900 lb. | 900 lb. |

| Module 4.0 | 13,000 lb. | 6,700 lb. | 3,600 lb. | 1,800 lb. |

| Module 5.0 | 16,000 lb. | 10,000 lb. | --- | 2,900 lb. |

| Module 6.0 | 24,000 lb. | 15,000 lb. | --- | 4,200 lb. |

| Module 8.0 | 42,000 lb. | 26,000 lb. | --- | 7,600 lb. |

| Module 10.0 | 64,000 lb. | 40,000 lb. | --- | 12,000 lb |

| Module 12.0 | 92,000 lb. | 56,000 lb. | --- | --- |

| Module 16.0 | Please consult the factory! | |||

* Ratings are based on helical rack with a 25 tooth hardened & ground pinion; using smaller pinions would reduce rating. The ratings are based on fatigue strength with adequate lubrication; breaking strength ratings are much higher. Service factors need to be applied to these ratings to make a proper selection. The rack mounting screw holding force may also need to be checked.

Helical Rack Ratings | Straight Rack Ratings

What is a Module? Module is a metric pitch, inversely related to diametral pitch, e.g. Module = 25.4 / Diametral Pitch.

For application & selection assistance, please call us or fill out our Application Sheet. Your application data will be reviewed by our engineers, who will recommend the best solution for your application.

To view the rack dimensions, please click on the "Series" in left column.

| Series |

Style | Rack Description | Modules Available | Tooth Heat Treatment |

Quality Level |

|---|---|---|---|---|---|

| 28 | Straight | Hardened & Ground | 2, 3, 4, 5, 6 8, 10, 12 |

Case-Hardened | DIN 6 (~AGMA 12) |

| 28a | Straight | Hardened & Ground | 2, 3, 4, 5, 6, 8 | Induction-Hardened | DIN 7 (~AGMA 11) |

| 28b | Straight | Hardened & Ground | 2, 3, 4, 5 | Induction-Hardened | DIN 8 (~AGMA 10) |

| 29 | Helical | Hardened & Ground | 2, 3, 4, 5, 6 8, 10, 12 |

Case-Hardened | DIN 6 (~AGMA 12) |

| 29a | Helical | Hardened & Ground | 2, 3, 4, 5, 6, 8, 10 | Induction-Hardened | DIN 7 (~AGMA 11) |

| 29b | Helical | Hardened & Ground | 2, 3, 4, 5, 6 | Induction-Hardened | DIN 8 (~AGMA 10) |

| 33 | Straight | Quenched & Tempered | 2, 3, 4 | Quenched & Tempered | DIN 8 (~AGMA 10) |

| 34 | Straight | Induction Hardened | 2, 3, 4, 5, 6 8, 10, 12 |

Induction Hardened | DIN 10 (~AGMA 8) |

| 38 | Helical | Quenched & Tempered | 2, 3, 4 | Quenched & Tempered | DIN 8 (~AGMA 10) |

| 39 | Helical | Induction Hardened | 2, 3, 4, 5, 6 8, 10, 12 |

Induction Hardened | DIN 10 (~AGMA 8) |

| 47 | Helical | Soft | 1.5, 2, 3, 4 5, 6, 8, 10 |

None | DIN 9 (~AGMA 9) |

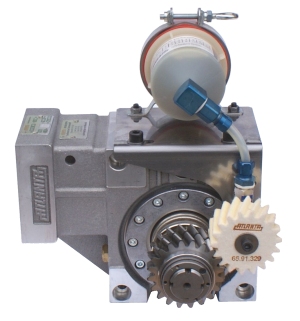

With open gearing such as rack & pinions, lubrication is critical! A thin film of grease or oil should always be on the contacting tooth flanks to ensure there is no metal-to-metal contact, which can damage the teeth.

With open gearing such as rack & pinions, lubrication is critical! A thin film of grease or oil should always be on the contacting tooth flanks to ensure there is no metal-to-metal contact, which can damage the teeth.

It is recommended to use our Automatic Lubrication System, which pumps grease through a felt gear applicator and meshes directly to the pinion or the rack. This provides continuous lubrication at the tooth flanks, extending the lifetime and maintaining the quality of the gearing.

For more information on our Automatic Lubrication Systems, please follow this link.