Advantages of Using Small Pinions

When it comes to selecting a pinion for use in a rack & pinion drive system, the pinion pitch diameter can have a huge effect on the system. ATLANTA has a wide range of pinions, including ISO flanged pinions, which gives the design engineer flexibility to optimize his design.

The new ATLANTA TR ISO flanged pinions have pitch diameters smaller than their bolt circle diameter, which reduces the torque and reduction ratio required. The linear backlash from the gearbox is also reduced since the pinion radius is smaller.

Another significant impact of using smaller pinions can be seen on the linear stiffness relating to the gearbox torsional rigidity. This linear stiffness is inversely proportional to the square of the pinion diameter; therefore, using a pinion half of the size would improve the linear stiffness by a factor of four.

Example:

The best way to see all of the advantages of using smaller pinions can be seen in the below example.

Application Description:

A customer needs to move 7,000 lb. at a speed of 2,000 inches per minute, with an acceleration rate of 66.67 inches per second squared. The acceleration force to make this move is calculated at 1,489 lb.

System Comparison:

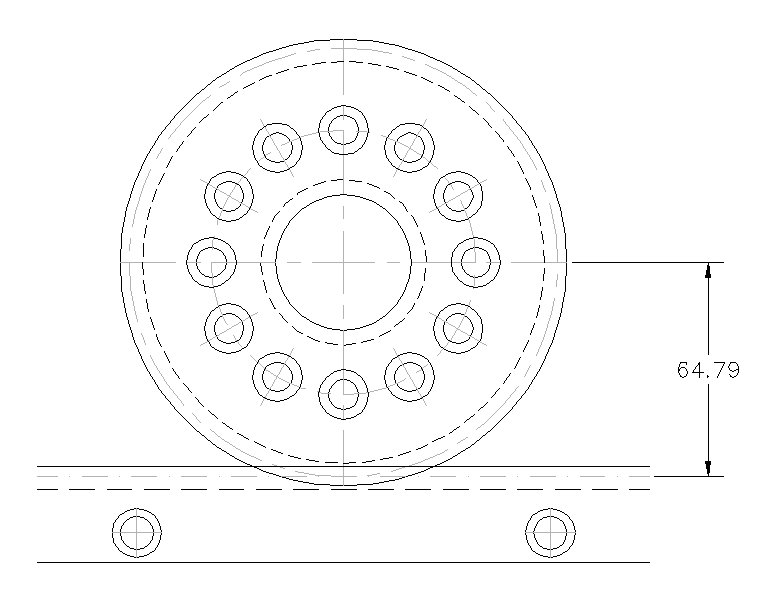

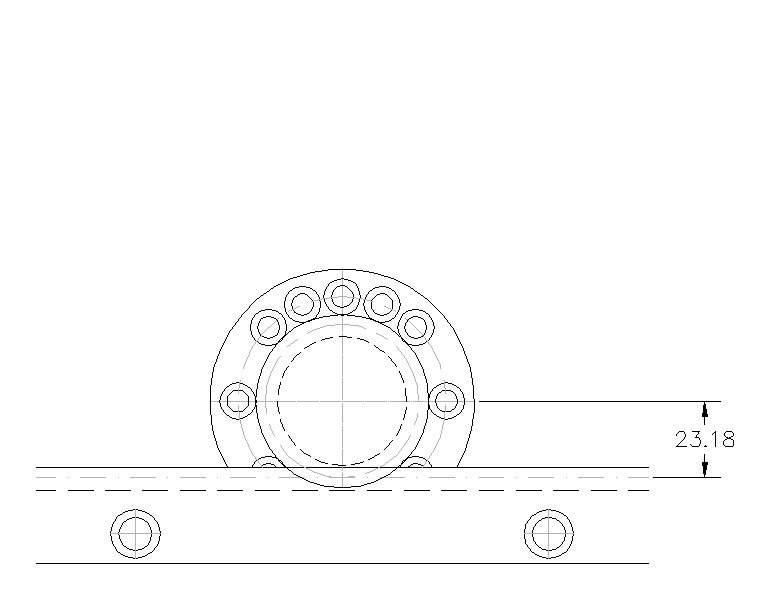

A 40-tooth helical module 3.0 pinion with a pitch radius of 64.79 mm was selected, and a 14-tooth helical module 3.0 pinion with a pitch radius of 23.18 mm was selected to compare to.

The following table compares the various system parameters for both pinion solutions:

| System Parameter | Using 40-Tooth Pinion | Using 14-Tooth Pinion |

|---|---|---|

| Required Torque | 311 lb.ft. | 109 lb.ft. |

| Gearbox Size | 140 mm | 110 mm |

| Gearbox Ratio | 20:1 (Two-Stage) | 7:1 (Single-Stage) |

| Linear Gearbox Backlash | 0.0022" | 0.0008" |

| Linear Gearbox Stiffness | 127 N/micron | 533 N/micron |

| Resonant Frequency | 31.86 Hz | 65.22 Hz |

From this example, it is clear that by using a smaller pinion, the following design advantages can be achieved:

- The required torque is reduced dramatically, from 311 lb.ft. to 109 lb.ft.

- The gearbox size drops from a 140 mm diameter to a 110 mm diameter

- A smaller reduction ratio can be used in the gearbox, going from a two-stage gearbox to a single stage gearbox.

- The linear backlash is reduced by two-thirds, from 0.0022" to 0.0008"

- The linear stiffness is increased by a factor of four, from 127 N/micron to 533 N/micron

- The resonant frequency of the system more than doubles, from 31.86 Hz to 65.22 Hz!

Conclusion

The advantages of using ATLANTA small pinions can be easily seen with the following design advantages:

- Reduced torque required

- Reduced gearbox ratio required, saving money

- Smaller gearbox can typically be used, saving money

- Smaller design envelope required

- Reduced linear gearbox backlash

- Increased linear gearbox stiffness

- Increased resonant frequency of system