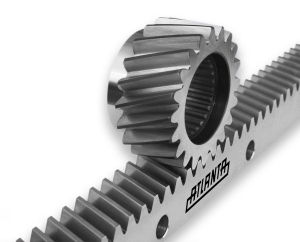

Pinion Gears

Welcome to the widest range of standard racks & pinions in the World! Consisting of both helical & straight (spur) tooth versions, in an assortment of sizes, materials and quality levels, to meet almost any axis drive requirements.

These drives are perfect for a wide range of applications, including axis drives requiring precise positioning & repeatability, traveling gantries & columns, pick & place robots, CNC routers and material handling systems. Heavy load capacities and duty cycles can also be easily handled with drives. Industries served include Material Handling, Automation, Automotive, Aerospace, Machine Tool and Robotics.

The pinion product range consists of metric pitches from module 1.0 to 12.0, in various styles including helical, straight (spur), ISO flanged, split-pinion (zero backlash) and circular pitch. Quality levels available include soft, induction-hardened and hardened & ground (up to AGMA 12+ and DIN 5).

Typical delivery time for these standard components is 2 to 3 weeks, which is ideal for OEM's requiring just-in-time delivery schedules. Special and/or modified components are always possible - please consult the factory.

Advantages of Using Small Pinions: When it comes to selecting a pinion for use in a rack & pinion drive system, the pinion diameter has a huge effect on the system, including the gearbox torque, size, ratio, linear backlash, linear stiffness and resonant frequency of the system.

- Pinion Styles

Available - Pinion Gear Quality

Levels Overview - Pinion Range

Overview - Lubrication

There are five basic pinion gear styles available (click on style for PDF catalog pages):

A Compression Coupling can be used on pinions with side hubs to attach the pinion to the shaft without any backlash. This option, which can be used in conjunction with a key, is best for applications with high reversing cycles and eliminates the possibility of fretting corrosion.

Helical versus Straight: The helical style provides several key benefits over the straight style, including:

- They run quieter than the straight, especially at high speeds

- They have a higher contact ratio (the number of effective teeth engaged) than straight, which increases the load carrying capacity

- In most cases, they cost the same as the straight pinions!

The only possible disadvantage to using helical rack & pinions is that they could require more time to set up and align properly.

There are three basic quality levels of pinion gears: Click on Series Numbers for PDF catalog pages.

| Pinion Type: | Tooth Quality: |

Typical Applications: |

Helical: |

Straight: |

|---|---|---|---|---|

| Soft | DIN 8 (~AGMA 10) |

Light Loads Medium Accuracy |

21 Series | 21 Series 06-Series (Stainless) Cast Iron & Plastic |

| Induction Hardened* |

DIN 10 | Heavy Loads Low Accuracy |

21 Series | 21 Series |

| Hardened & Ground |

DIN 5 ISO Flanged |

Heavy Loads Ultra-High Accuracy |

78 Series | 78 Series |

| DIN 5 Splined |

79 Series | --- | ||

| DIN 6 Blank Bores |

Heavy Loads High Accuracy |

24.99 Series | 24.98 Series | |

| DIN 7 | 24 Series | 24 Series |

* Induction-Hardened pinions are made from soft pinions.

For most rack and pinion applications, a hardened & ground pinion is typically used since it sees the most cycles. The pinion is usually harder than the rack for this reason.

Click on the "Series" number in left column to view associated PDF catalog page.

| Series |

Style | Pinion Description | Modules Available | Tooth Heat Treatment |

Quality Level |

|---|---|---|---|---|---|

| 06 | Straight | Soft, Stainless | 1, 1.5, 2, 3 | None | ~AGMA 10 |

| 07 | Straight | Soft | 5 & 10 mm Circular Pitch |

Optional | ~AGMA 10 |

| 20 | Straight & Helical |

Hardened & Ground Pinion Shafts |

2, 3, 4, 5, 6 | Case-Hardened | ~AGMA 12 |

| 21 | Straight | Soft | 1, 1.5, 2, 2.5, 3, 4, 5, 6, 8 | Optional | ~AGMA 10 |

| 21 | Helical | Soft | 2, 3, 4, 5, 6, 8 | Optional | ~AGMA 10 |

| 22 | Straight | Plastic | 1, 1.5, 2, 2.5, 3 | None | ~AGMA 9 |

| 23 | Straight | Cast Iron | 1.5, 2, 2.5, 3, 4, 5, 6 | None | ~AGMA 10 |

| 24 | Straight | Hardened & Ground |

2, 3, 4, 5, 6 | Case-Hardened | ~AGMA 11 |

| 24.98 | Straight | Hardened & Ground with Blank Bores |

2, 3, 4, 5 | Case-Hardened | DIN 6 |

| 24 | Helical | Hardened & Ground |

2, 3, 4, 5, 6, 8 | Case-Hardened | ~AGMA 11 |

| 24.99 | Helical | Hardened & Ground with Blank Bores |

2, 3, 4, 5, 6, 8 | Case-Hardened | DIN 6 |

| 24.0 | Straight | Hardened & Ground |

5, 10 & 13.33 mm Circular Pitch |

Case-Hardened | ~AGMA 11 |

| 74 | Helical | Hardened & Ground Split-Pinions |

2, 3, 4, 5, 6, 8 | Case-Hardened | ~AGMA 11 |

| 78 | Helical | ISO 9409-1-A Flanged | 2, 3, 4, 5 | Case-Hardened | DIN 5 |

| 78h | Helical | TR ISO 9409-1-A Flanged | 2, 3, 4, 5, 6, 8 | Case-Hardened | DIN 5 |

| 78s | Straight | TR ISO 9409-1-A Flanged | 2, 3, 4, 5, 6, 8 | Case-Hardened | DIN 5 |

| 79 | Helical | DIN 5480 Splined Bore | 2, 3, 4 | Case-Hardened | ~AGMA 12 |

| 80 | Compression Couplings | ||||

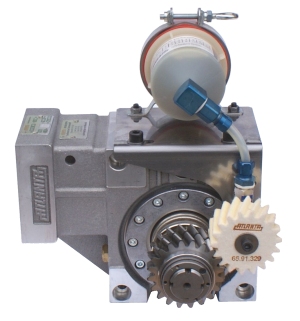

With open gearing such as rack & pinions, lubrication is critical! A thin film of grease or oil should always be on the contacting tooth flanks to ensure there is no metal-to-metal contact, which can damage the teeth.

With open gearing such as rack & pinions, lubrication is critical! A thin film of grease or oil should always be on the contacting tooth flanks to ensure there is no metal-to-metal contact, which can damage the teeth.

It is recommended to use our Automatic Lubrication System, which pumps grease through a felt gear applicator and meshes directly to the pinion or the rack. This provides continuous lubrication at the tooth flanks, extending the lifetime and maintaining the quality of the gearing.

For more information on our Automatic Lubrication Systems, please follow this link.