Other Products Available

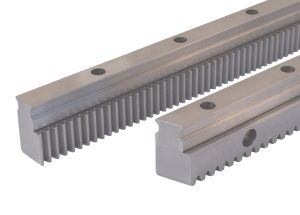

Advantages of Using Long Racks

Through continuous improvements in production techniques, ATLANTA has been able to reduce the total pitch error for the 1,000 mm long hardened & ground racks, while achieving significant reductions of the total pitch error of 1,500 mm and 2,000 mm long hardened & ground racks. Therefore, for long travel lengths, it is possible to minimize the total pitch error seen.

Using long racks reduces the number of rack sections, which reduces the amount of time needed to mount the racks. It is also advantageous to use longer racks to reduce the number of rack joints, which can induce further error into the axis.

The new rack pitch error (GTf) values are as follows:

| Rack Quality | 1,000 mm Rack | 1,500 mm Rack (GTf/1,500) | 2,000 mm Rack (GTf/2,000) |

|---|---|---|---|

| 5 | 0.026 mm | 0.031 mm (0.021 mm/1,000 mm) | 0.034 mm (0.017 mm/1,000 mm) |

| 6 | 0.034 mm | 0.041 mm (0.027 mm/1,000 mm) | 0.044 mm (0.022 mm/1,000 mm) |

| 7 | 0.052 mm | 0.062 mm (0.041 mm/1,000 mm) | 0.068 mm (0.034 mm/1,000 mm) |

Mounting Example:

The best way to see the advantages of using long racks is the below mounting example comparing using 0.5, 1.0 and 2.0 meter long racks.

- Travel Length: 6 meters, racks mounted end-to-end with companion rack

- Error at Rack Joints from Companion Rack: < 0.025 mm

Using 3 pieces of 29.40.205 DIN 6 helical module 4.0 hardened & ground two-meter long rack:

- Pitch Error per rack GTf/2,000 = 0.044 mm

- Total Pitch Error: 3 x 0.044 (racks) + 2 x 0.025 (rack joints) = 0.182 mm

- Mounting Required: # of Screws Required = 3 x 16 = 48, Rack Joints = 2, Dowel Pins Required = Zero

Using 6 pieces of 29.40.105 DIN 6 helical module 4.0 hardened & ground one-meter long rack:

- Pitch Error per rack GTf/1,000 = 0.034 mm

- Total Pitch Error: 6 x 0.034 (racks) + 5 x 0.025 (rack joints) = 0.329 mm

- Mounting Required: # of Screws Required = 6 x 8 = 48, Rack Joints = 5, Dowel Pins Required = Zero

Using 12 pieces of 29.40.055 DIN 6 helical module 4.0 hardened & ground half-meter long rack:

- Pitch Error per rack GTf/500 = 0.026 mm

- Total Pitch Error: 12 x 0.026 (racks) + 11 x 0.025 (rack joints) = 0.587 mm

- Mounting Required: # of Screws Required = 12 x 4 = 48, Rack Joints = 11, Dowel Pins Required = 24

If the ATLANTA Rack Assembly Kit is used instead of a companion rack, the total pitch error is reduced even further:

- Error at Rack Joints from Rack Assembly Kit: < 0.005 mm

- With 2.0 Meter Racks: Total Pitch Error reduced to 0.142 mm (-21%)

- With 1.0 Meter Racks: Total Pitch Error reduced to 0.229 mm (-30%)

- With 0.5 Meter Racks: Total Pitch Error reduced to 0.367 mm (-37%)

Conclusion

The advantages of using ATLANTA long racks can be easily seen with the following design advantages:

- Reduced Pitch Error values

- Reduced number of rack sections required

- Reduced amount of time needed to mount the racks

- Reduced the number of rack joints