Other Products Available

Separating Rack & Pinion Myths From Reality

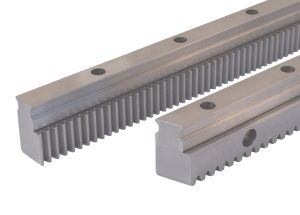

Rack and pinion drives are an age-old mechanism widely used for converting rotary motion to linear motion.

However, myths and misconceptions abound regarding the use and application of rack & pinions in this age of servo-driven machinery.

It is the hope of this article is to address and debunk some of those myths and misconceptions once and for all.

Reality:

It is true that Rack & Pinions are an old technology, but that isn’t necessarily a bad thing. Firstly, not all applications require high precision; material handling applications can have very low accuracy requirements.

Secondly, advances in gear production techniques (milling, grinding, heat treatment, etc.) have dramatically improved the precision and load carrying capacity of rack & pinion drives, to the point that they are still a very competitive solution to any linear axis drive applications.

Rack & Pinion drives with low (or zero) backlash and low (or zero) pitch error are now possible!

Reality:

Rack & Pinions have a theoretical center distance at which optimal meshing occurs. By pushing the pinion into the rack, you can reduce the backlash level but you also negatively affect the tooth meshing, which can cause excessive wear and binding.

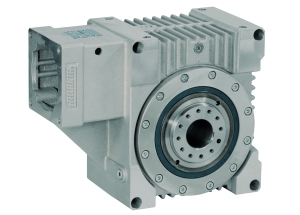

The best way to reduce the backlash of a rack & pinion drive would be to increase the quality level of the teeth, as well as their mounting accuracy. To completely remove the backlash of a rack & pinion drive, a split-pinion or dual-pinion drive can be used, where one pinion drives while the other removes the backlash.

Reality:

Rack & Pinions are considered open gearing because they are not enclosed in a housing, so foreign debris can find its way into the tooth mesh and cause damage. However, by orienting the rack teeth on their side or facing down, this can be minimized. Linear bellows or covers can also be used to protect the drive.

By using an automatic lubrication system with a felt gear applicator, any debris on the tooth flanks can be wiped away so damage is prevented.

For washdown or wet environments, stainless steel rack & pinions can be used to prevent corrosion.

Reality:

To achieve the desired travel length, multiple pieces of rack may be mounted end-to-end. During assembly, errors can be induced into the drive where the rack sections butt together.

Using a “companion” rack, which meshes between the two rack sections, this error can be minimized. Perfect rack joints with no error can be achieved by using a rack assembly kit, which allows for the joint to be precisely measured and any error eliminated.

Reality:

For long axis drives, multiple pieces of rack may be mounted end-to-end to achieve the desired travel length. Although each piece of rack has an overall pitch error associated with it, this error can be controlled or even eliminated so that there is no accumulated error over the full travel length.

Depending on the quality level of the rack teeth, the pitch error can be between 0.012 mm and 0.200 mm per meter length. It is also possible to mount racks in a predefined order to always have the total pitch error hover around zero.

Reality:

Split-pinions consist of two pinion halves – one which is fixed and one which is axially spring-loaded. Before operating, the split-pinion is first adjusted to remove the mesh backlash; it is then preloaded to compress the spring up to the operating load of the application.

Preloading the spring ensures that the spring will NOT deflect under load during operation. In fact, when the preload is set properly, the spring will not move at all during operation. The only way the spring could deflect further is if the operating load exceeds the preload setting.

Reality:

Ballscrews can provide adequate performance for axis drives requiring precise positioning and repeatability. They can achieve this by having low backlash and pitch error; zero backlash can be achieved by using preloaded nuts.

Rack & Pinions can also achieve precise positioning and repeatability. Using hardened & ground tooth flanks, low backlash and pitch error can be achieved; zero backlash can be achieved by using split-pinion or dual-pinion drives.

For long and heavy axis drives, such as those found in the Machine Tool and Aerospace industries, rack & pinions can actually out-perform ballscrews, since their travel lengths are limited by their buckling strength and whip. For high-speed applications, rack & pinion drives can also handle higher linear speeds (up to six meters per second) than ballscrews.

Roller-pinions are a simplistic drive system which uses rollers instead of teeth to engage a rack. These drives claim to have zero backlash since multiple rollers are engaged at one time. However, these drives require preloading of the rollers into the rack to ensure optimal meshing. This preloading can fluctuate up and down depending on the mounting accuracy of the rack. If the preload is lost, backlash can develop; if the preload is excessive, the roller-pinion can develop vibration & noise, and lead to premature failure.

Rack & Pinion drives can achieve zero backlash by use of a split-pinion or dual-pinion to preload the axis. The preload is set either either mechanically (split-pinion) or electrically (dual-pinion) and is always present and is independent of the mounting accuracy of the rack. For high load applications, rack & pinion drives can out-perform roller-pinion drives due to their limited load capacity and stiffness.

Reality:

Rack & Pinions can be used on any machine requiring conversion of rotary motion to linear motion. From simple, low-accuracy applications to the most demanding high-precision applications, they can be selected and applied to achieve the desired axis performance without any sacrifices.

Typical applications for Rack & Pinions include, but are not limited to: CNC routers, pick-and-place robots, traveling gantries, material handling, automation, machine tool, aerospace, woodworking, stir friction welding, carbon fiber placement and seventh-axis robotic slides.