Related Resources

Operating Manuals Automatic Lubrication Systems PDF Application Sheets Frequently Asked QuestionsOther Products Available

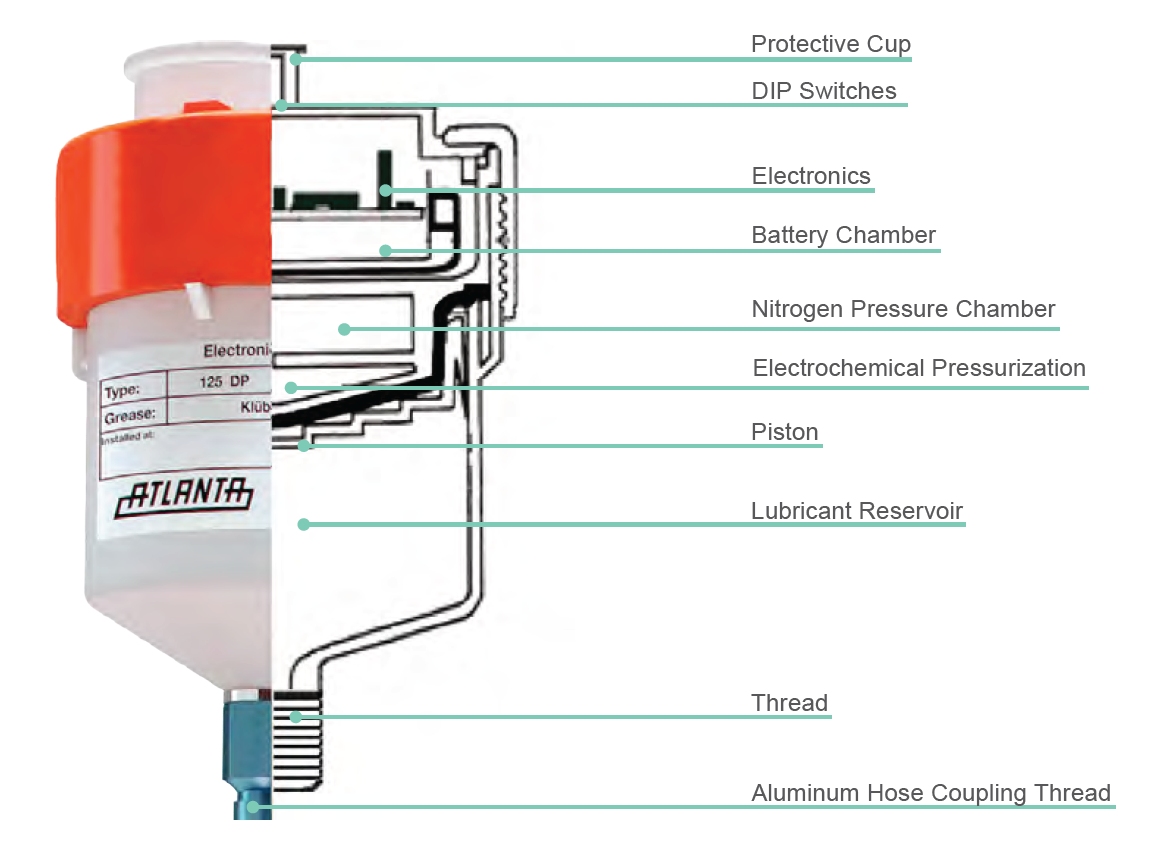

Automatic Lubricators - Type 125 & 475 (Classic)

These single-point lubricators are electronically controlled lubricators which offer precise, reliable delivery of lubricant based on the grease gun principle. After setting the dip-switch settings on the lubricator, nitrogen gas is generated electronically to build pressure and move an internal piston.

The grease flow is pushed out continuously (not pulsating) at constant pressure according to the selected flow rate. Depending on application requirements, an emptying time of 1 to 18 months can be selected by setting the dip-switches on the lubricator.

The transparent housing, which can be mounted in any position, allows for a visual check of grease level still available. Once the lubricator is completely empty, it is possible to refill and reuse it.

For more detailed information, please check out the PDF catalog here.

Specifications

| Model | 125 | 475 | |

|---|---|---|---|

| Pump Type | Nitrogen Pressure Chamber (Replaceable) | ||

| Operating Pressure | 0.2 - 3.0 bar | ||

| Empty Time | 1 to 18 months | Empty Sensor | Visual |

| Time or Pulse Control | Time Mode | ||

| Lubricant Amount | 100 cc | 460 cc | |

| Lubricant Types | Oils and Greases up to NLGI 1 | ||

| Operating Temperature Range | -30º C to +50º C | ||

| Operating Voltage | 3V (Batteries or External Power) | ||

| Weight Empty | 420 g | 600 g | |

| Dimensions H x Ø | 10.0 x 8.0 cm | 15.0 x 11.5 cm | |

| Outlet Port Size | G1/4" (ATEX - G1/8") | G1/2" (ATEX - G1/4") | |

| Performance Monitoring | Red / Green LED | ||

| Machine Synchronization | With Contact Cable | ||

| ATEX Available | II 2G Ex ib IIC T4 / T3 Gb | ||

Lubricant Flow Rates

The following table shows the lubricant flow rates of the automatic lubricators.

| Lubricant Per Day (cc) | Lubrication Cycle | Lubricant | Months To Empty | DIP-Switch Setting | |

|---|---|---|---|---|---|

| Model 125 | Model 475 | ||||

| 4.00 | 14.00 | Continuous | 1 | 1+7 | |

| 2.10 | 7.50 | 2 | 2+7 | ||

| 1.30 | 4,50 | 3 | 3+7 | ||

| 0.70 | 2.50 | 6 | 4+7 | ||

| 0.35 | 1.20 | 12 | 5+7 | ||

| 0.175 | 0.60 | 18 | 6+7 | ||

Lubricator Design