Rack & Pinion Drive Systems

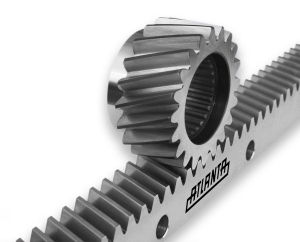

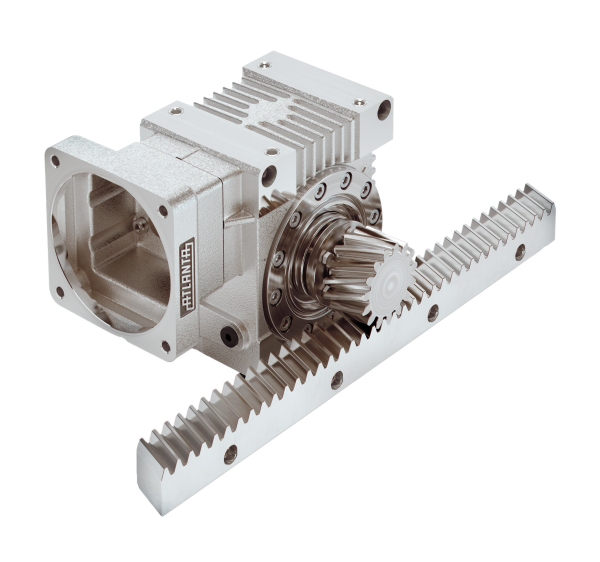

ATLANTA Drive Systems offers a complete range of Rack & Pinion Drive Systems, which consist of a servo reducer with a mounted pinion on the output and the driven gear rack. By selecting the complete drive system all at once, a system can be optimized for the servo motor while achieving the desired accuracy and motion at the rack & pinion.

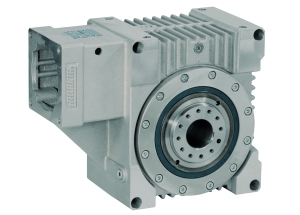

These systems are available in five levels of precision to meet any axis drive requirements. They utilize our wide range of standard Rack & Pinions (quality levels from DIN 4 to DIN 10) and Servo Reducers, which are available in-line (motor is in-line with pinion) and right-angle (motor is at a right-angle to pinion) versions to fit into most designs.

These systems are available in five levels of precision to meet any axis drive requirements. They utilize our wide range of standard Rack & Pinions (quality levels from DIN 4 to DIN 10) and Servo Reducers, which are available in-line (motor is in-line with pinion) and right-angle (motor is at a right-angle to pinion) versions to fit into most designs.

These drive systems are perfect for a wide range of applications, including axis drives requiring precise positioning & repeatability, traveling gantries & columns, pick & place robots, CNC routers and material handling systems. Heavy load capacities and duty cycles can also be easily handled with these drives. Industries served include Material Handling, Automation, Automotive, Aerospace, Machine Tool and Robotics.

Considering a Roller-Pinion System (RPS)? For a comparison of ATLANTA Rack & Pinion Drive Systems to Roller-Pinion Systems (RPS), please follow this link.

ATLANTA Industry 4.0 Website is now live! With this website you have access to product data of ATLANTA racks and servo worm reducers, operating manuals, as well as special features such as rack mapping. With the world’s first "digital rack" from ATLANTA, you can enter the world of smart drive technology of tomorrow, providing machine builders huge performance improvements and productivity gains.

System Overview

There are five levels of system precision, each of which is well suited for certain types of applications (click on level for more information):

| System Precision Level: |

Rack Type & Class: | Rack Quality Level: |

Rack Pitch Error: |

Rack & Pinion Minimum Backlash: * |

Drive Force Capacity: |

|---|---|---|---|---|---|

| Ultra-High | Hardened & Ground (UHPR & HPR) |

DIN 3 to 6 (~AGMA 12+) |

< 0.012 to 0.036 mm per meter |

Zero | up to 28,000 lb. |

| High | Hardened & Ground (UHPR & HPR) |

DIN 3 to 6 (~AGMA 12+) |

< 0.012 to 0.036 mm per meter |

0.02 mm | up to 28,000 lb. |

| Medium | Quenched & Tempered (PR) |

DIN 8 (~AGMA 10) |

< 0.100 mm per meter |

0.04 mm | up to 4,300 lb. |

| Medium-Soft | Soft (BR) |

DIN 9 (~AGMA 9) |

< 0.150 mm per meter |

0.06 mm | up to 3,400 lb. |

| Low | Induction-Hardened (BR) |

DIN 10 (~AGMA 8) |

< 0.200 mm per meter |

0.08 mm | up to 10,000 lb. |

* The rack and pinion backlash depends on the alignment of the rack to the linear guides.