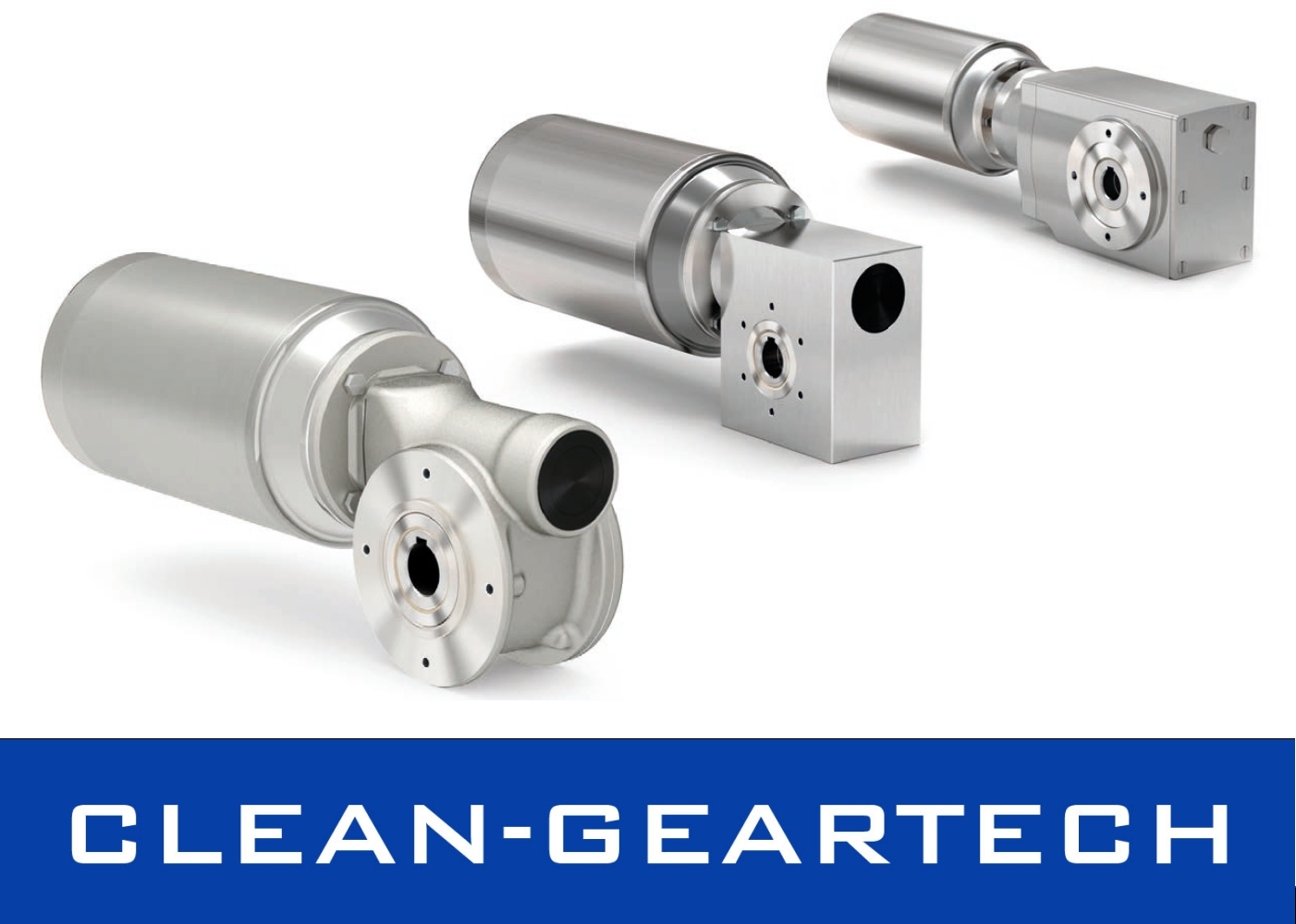

Washdown Drives

This standard range of Washdown Gearboxes are perfect for use in demanding applications in the Food & Beverage, Meat & Poultry, Marine, Chemical and Pharmaceutical Industries.

This standard range of Washdown Gearboxes are perfect for use in demanding applications in the Food & Beverage, Meat & Poultry, Marine, Chemical and Pharmaceutical Industries.

They are ideal for applications that have direct contact with food products which require washdown under high pressure and are available with ATEX and IP69k protection.

The washdown gearboxes are offered with corrosion protection depending on the environment they are exposed to and are available in the following versions:

| VFD (D-Series) Coated Aluminum Worm Gearboxes |

VFN (N-Series) Stainless Steel 316L Round Worm Gearboxes |

VFI (I-Series) Stainless Steel 304 Square Worm Gearboxes |

BVN (N-Series) Stainless Steel 316L Helical-Bevel Gearboxes |

|---|---|---|---|

Metric |

Metric |

Metric |

Metric |

They are available in reduction ratios from 5:1 to 2,856:1, with output torque capacities up to 498 lb.ft. (675 Nm) and input powers up to 5.4 hp (4.0 kW).

Our complete washdown drives catalogs can be found here:

- Metric Washdown Drives Catalog

- NEMA Washdown Drives Catalog

Unit design benefits include:

Unit design benefits include:

- Housings with smooth surfaces

- Stainless steel 316L output shafts

- Viton seals with stainless steel 316L shield

- Hardened & ground gearing

- All stainless steel 316L hardware

- Closed stainless steel 316L protection cap with o-ring

- Fully modular IEC and NEMA C motor flanges

Stainless steel and aluminum washdown motors are also available in powers up to 4.0 HP (3.0 kW) in voltages from 230V to 575V. They are totally enclosed, non-ventilated (TENV), IE4 efficiency class, and are available with metric IEC and NEMA flanges, in 2, 4 and 6 poles versions.

- Unit Ratings

- Unit Selection

The following table gives the technical specifications for various washdown gearboxes. Service factors need to be applied to these ratings to make a proper selection.

| Series | Size | Ratios | Output Torque (lb.ft.) |

||

|---|---|---|---|---|---|

VFD (D-Series)Coated Round AluminumWorm Gearboxes |

D30 | 5 to 100:1 | 15.5 | Metric |

--- |

| 3D3 | 150 to 2400:1 | 25.8 | Metric |

--- | |

| D45 | 7 to 102:1 | 30.2 | Metric |

NEMA |

|

| D45-211D | 14.35 to 1002.66:1 | 34.6 | Metric |

--- | |

| 4D3 | 140 to 2400:1 | 50.8 | Metric |

--- | |

| D50 | 7 to 100:1 | 53.1 | Metric |

NEMA |

|

| D50-211D | 14.35 to 983:1 | 61.2 | Metric |

--- | |

| 5D3 | 252 to 2400:1 | 80.38 | Metric |

--- | |

| D63 | 7 to 94:1 | 108.4 | Metric |

NEMA |

|

| D63-211D | 14.35 to 924.02:1 | 124.65 | Metric |

--- | |

| 6D3 | 2520 to 2745:1 | 169.6 | Metric |

--- | |

| 6D4 | 252 to 2520:1 | 195.4 | Metric |

--- | |

| D85 | 7 to 96:1 | 260 | Metric |

NEMA |

|

| D85-211D | 14.35 to 943.68:1 | 293.5 | Metric |

--- | |

| 8D4 | 140 to 2856:1 | 382.0 | Metric |

--- | |

VFN (N-Series)Round Stainless SteelWorm Gearboxes |

N30 | 5 to 100:1 | 15.5 | Metric |

--- |

| N45 | 7 to 102:1 | 30.2 | Metric |

NEMA |

|

| N45-211N | 14.35 to 1002.66:1 | 34.6 | Metric |

--- | |

| N50 | 7 to 100:1 | 53.1 | Metric |

NEMA |

|

| N50-211N | 14.35 to 983:1 | 61.2 | Metric |

--- | |

| N63 | 7 to 94:1 | 108.4 | Metric |

NEMA |

|

| N63-211N | 14.35 to 924.02:1 | 124.6 | Metric |

--- | |

| N85 | 7 to 96:1 | 260 | Metric |

NEMA |

|

| N85-211N | 14.35 to 943.68:1 | 293.5 | Metric |

--- | |

VFI (I-Series)Square Stainless SteelWorm Gearboxes |

I30 | 5 to 100:1 | 15.5 | Metric |

--- |

| I45 | 7 to 102:1 | 30.2 | Metric |

NEMA |

|

| I50 | 7 to 100:1 | 53.1 | Metric |

NEMA |

|

| I63 | 7 to 94:1 | 108.4 | Metric |

NEMA |

|

| I85 | 7 to 96:1 | 260 | Metric |

NEMA |

|

| I11 | 7 to 99:1 | 480 | Metric |

NEMA |

|

BVN (N-Series)Stainless SteelHelical-Bevel Gearboxes |

X42N | 7.29 to 77.36 | 95.9 | Metric |

NEMA |

| X43N | 50.35 to 323.37:1 | 100.3 | Metric |

NEMA |

|

| X62N | 6.03 to 74.81:1 | 302.4 | Metric |

NEMA |

|

| X63N | 56.76 to 589.85:1 | 302.4 | Metric |

NEMA |

|

| X73N | 7.94 to 86.09:1 | 498 | Metric |

NEMA |

|

| X74N | 74.79 to 678.79:1 | 498 | Metric |

NEMA |

|

These reducers are typically selected based on the input motor size and running output torque.

For application & selection assistance, please call, fax or email us. Your application information will be reviewed by our engineers, who will recommend the best solution for your application.

Applications

Typical applications for these gearboxes include: Transport conveyors, sorting machines, cleaning/washing machines, filling/dosing/dispensing machines, drying machines, heating/freezing machines, packaging machines, palletizing machines, bucket elevators, pump drives (diaphragm metering, rotary lobe, screw spindle, centrifugal, impeller), marine (anchor winch, capstan), candy machines, bakery ovens, and feed extruders.

Application Examples:

Application |

Conditions |

Possible Contact With |

Only In Proximity With |

||

|---|---|---|---|---|---|

| High | Medium | High | Medium | ||

| Meat & Poultry | Salt | I & N-Series | I & N-Series | ||

| Acid Sanitization | I & N-Series | I & N-Series | |||

| Alkaline Sanitization | I & N-Series | I & N-Series | I & N-Series | D-Series | |

| Normal Cleaning | I & N-Series | D-Series | D-Series | ||

| Seafood Processing | Salt | I & N-Series | I & N-Series | ||

| Acid Sanitization | I & N-Series | I & N-Series | |||

| Alkaline Sanitization | I & N-Series | I & N-Series | I & N-Series | D-Series | |

| Normal Cleaning | I & N-Series | I & N-Series | D-Series | ||

| Fruit & Vegetables | Salt | I & N-Series | |||

| Acid Sanitization | I & N-Series | ||||

| Alkaline Sanitization | I & N-Series | I & N-Series | I & N-Series | D-Series | |

| Normal Cleaning | I & N-Series | D-Series | D-Series | ||

| Dairy | Salt | I & N-Series | I & N-Series | ||

| Acid Sanitization | I & N-Series | I & N-Series | |||

| Alkaline Sanitization | I & N-Series | I & N-Series | D-Series | ||

| Normal Cleaning | I & N-Series | I & N-Series | D-Series | ||

| Flours & Derivatives | Salt | I & N-Series | |||

| Acid Sanitization | I & N-Series | ||||

| Alkaline Sanitization | I & N-Series | I & N-Series | D-Series | ||

| Normal Cleaning | I & N-Series | D-Series | D-Series | ||

| Beverages | Salt | I & N-Series | I & N-Series | ||

| Acid Sanitization | I & N-Series | I & N-Series | |||

| Alkaline Sanitization | I & N-Series | I & N-Series | D-Series | ||

| Normal Cleaning | I & N-Series | D-Series | D-Series | ||

| Food Packaging & Processing |

Salt | I & N-Series | I & N-Series | ||

| Acid Sanitization | I & N-Series | I & N-Series | |||

| Alkaline Sanitization | I & N-Series | I & N-Series | D-Series | ||

| Normal Cleaning | I & N-Series | D-Series | D-Series | ||

| Bakery | Salt | ||||

| Acid Sanitization | |||||

| Alkaline Sanitization | I & N-Series | D-Series | |||

| Normal Cleaning | I & N-Series | D-Series | D-Series | ||

| Animal Food | Salt | I & N-Series | I & N-Series | ||

| Acid Sanitization | I & N-Series | I & N-Series | |||

| Alkaline Sanitization | I & N-Series | D-Series | |||

| Normal Cleaning | I & N-Series | D-Series | D-Series | ||

| Marine | On Deck | I & N-Series | |||

| Indoor | I & N-Series | ||||